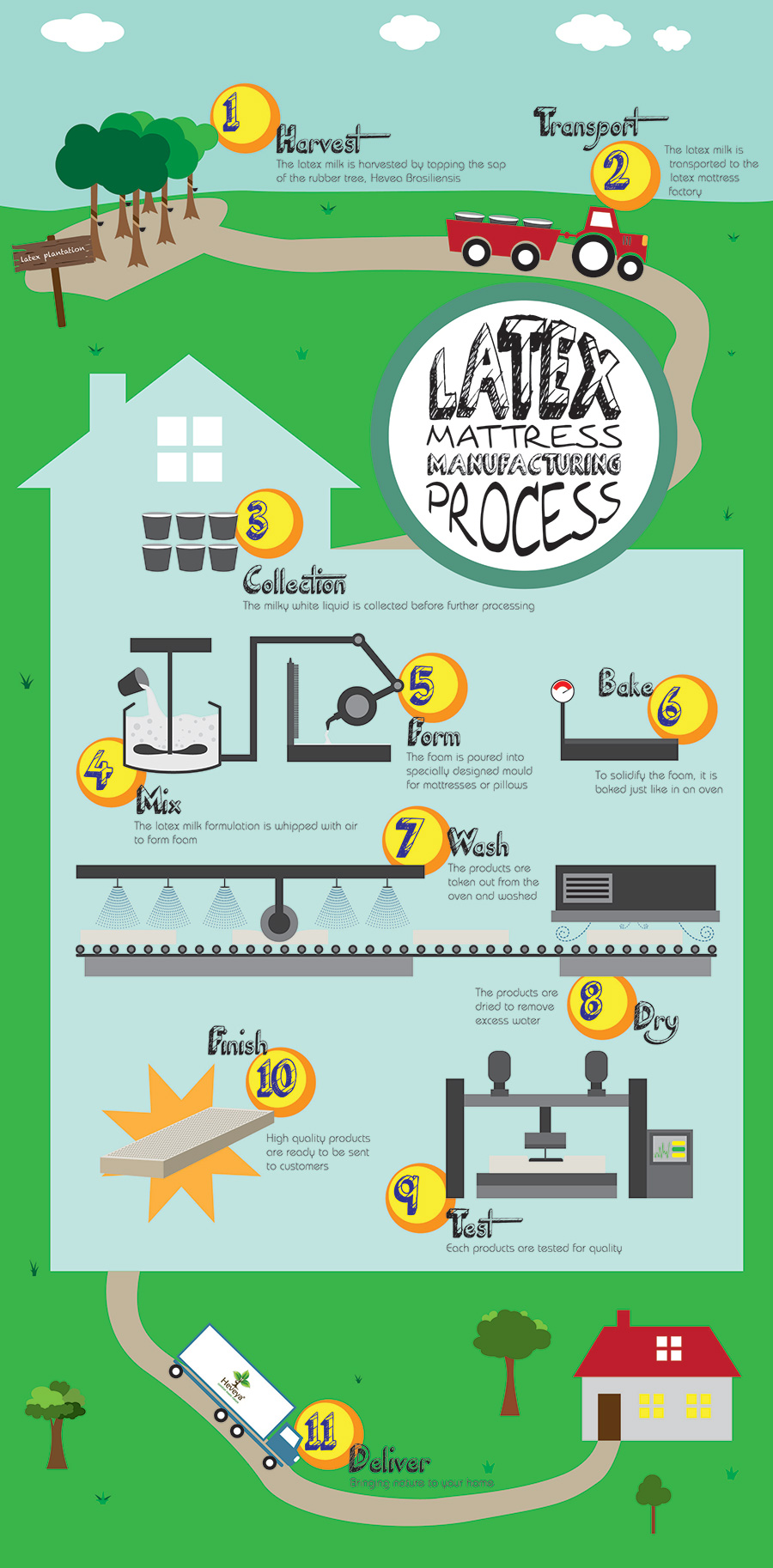

The Heveya organic latex mattress manufacturing process

Latex is a milky-white liquid sap that comes from the rubber tree. It consists of rubber particles, water and little contents of resins, sugar and ash. Due to its high elasticity, it is used to make rubber and other related products such as shoes, balloons, gloves, mattresses and many more. In fact, latex is one of the best natural materials to make mattresses because of its intrinsic characteristics: elastic, anti-dust mite and mould resistant.

Tapping of the latex

Natural latex is extracted from the Hevea Brasilienesis rubber tree as mentioned above and requires precise skill when harvesting latex from the tree barks. A worker cuts a strip of the bark halfway around the tree, about 0.84cm deep allowing the latex to exude into a collecting vessel for some hours about six hours. Large amount of organic latex is required to make a single mattress, for a king size, it would take at least a whole day's output of 12 acres of rubber trees. Important to note that harvesting the sap does not harm the tree. After the sap is collected, the tree bark heals quickly. The trees can yield latex milk for up to 25 to 30 years. After that, the trees are felled to be used for other purposes such as furniture and new trees can be replanted.

Heveya mattresses and pillows are made particularly from the sap of organic rubber. In other words, there is absolutely no pesticide or chemical used.

Manufacturing of latex mattresses

Ever wondered how a latex mattress is made out of some milky liquid? Well, latex mattress manufacturing process is quite an interesting one. Heveya latex mattresses and pillows are made using the Dunlop production process. The milky white liquid is usually composed of rubber particles dispersed in water. The material is then whipped with air to form foam and poured into specially designed ovens to be vulcanized, or, to be baked in simple terms. The mattresses and pillows that come out from the ovens are then washed, dried and passed through the quality test before they are ready to be made into finished products.

The other latex production method is called the Talalay process which involves three stages. That is, the use of closed mould with pre-vacuum (moulding), which is followed by freezing in order to maintain uniform bubble geometry. Usually, carbon dioxide is used unlike in the Dunlop production process where sodium fluorosilicate is used. The last step in the Talalay process is vulcanization whereby the foam is locked into a uniform bubble distribution.

Dunlop production process allows different sizes of mould needed to create the desired sizes and shapes whereas Talalay's mould sizes tend to be limited. With the Talalay method, certain mattress sizes need to be manufactured out of smaller blocks glued together. Dunlop mattresses are generally denser than Talalay which makes them a bit firmer, heavier and more durable.

Why choose organic latex mattresses?

Heveya organic latex mattresses are certified by different organizations and carry quality certificates that guarantee customers and users exceptional comfort and safety. They offer an ideally healthy and restful sleep. Allergic people should not worry as latex mattresses and pillows are anti-microbial, dust mite and mildew resistant. Since the mattresses are highly aerated due to the open-cell structure, they do not trap or absorb heat.

Finally, it is important to mention here that there is no chemical used in the production of our latex mattresses hence making them the safest of all and the most durable and resilient foam produced, something which makes it top among the best mattress values available today.